Nemak is a leading provider of innovative lightweighting solutions for the global automotive industry, specializing in the development and manufacturing of aluminum components for powertrain and body structure applications.

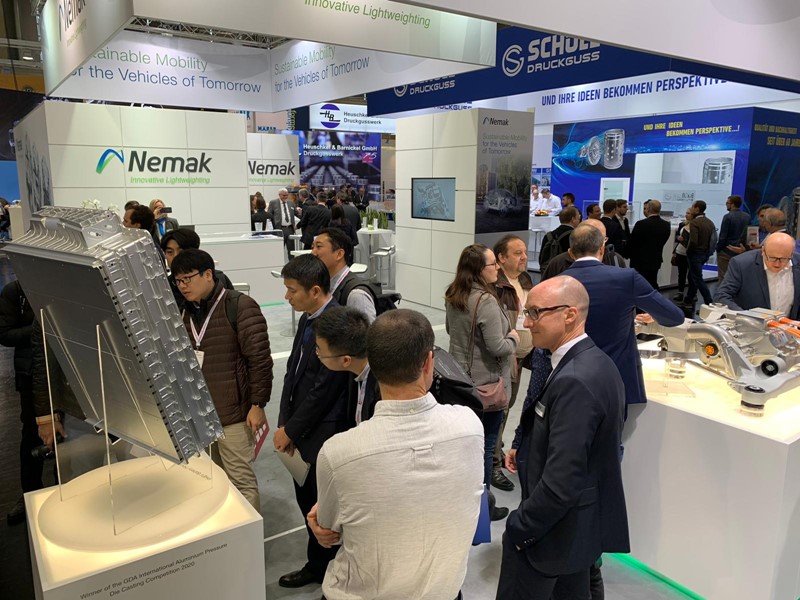

Nemak demonstrates its EV battery housing competence at EUROGUSS 2020

At this year’s EUROGUSS 2020 trade fair in Nuremberg, Nemak highlights typical problem areas in BEV battery housings and demonstrate innovative approaches to delivering tailor-made solutions.

In addition to its proven track record in aluminum casting, in the last decade the company has developed extensive know-how in complex assemblies involving different materials. Nemak offers ready-assembled battery housing solutions that, owing to their complexity, require a flexible, modular production concept. The requirement profile for battery housings is highly complex – from crash protection and tightness to solutions for battery cooling and ease of maintenance. For each of these challenges, Nemak has created innovative solution concepts that comply with the specific requirements of OEMs. The battery housing model on show at EUROGUSS 2020 demonstrates where the special challenges involved in the development and high volume serial production of a battery housing lie and how Nemak has overcome them with its innovative solutions.

“We offer our customers the opportunity to realize highly advanced and tailor-made solutions, from the conception phase through the development process and up to high volume serial production. This includes the entire product and process engineering - not only of the cast components but also of complex structural components subjected to high levels of stress. Here, joining technologies play a decisive role,” says Josef Nueschen, Director of Vehicle Structures at Nemak.

The battery housing model will clearly demonstrate these challenges. A series manufacturer of battery housings for electric vehicles must account for safety, tightness and tolerance requirements, as well as the assembly sequence and welding distortion. Manufacturing and business know-how regarding maintenance and repair in the ensuing period are also needed. Thanks to the demonstrator, the solution approaches developed by Nemak can be seen, named, and understood.

“The factors to consider are crash safety calculations,” explains Josef Nueschen, “and perfect integration into the chassis. And then again, there are the matters of battery cooling and tolerance management.” The demonstrator will clarify the importance of the joining concept to the bodywork and illustrate how the battery electronics can be functionally integrated using cast components, and it will also reveal how much know-how goes into the various production techniques employed.

An exemplary joining technology used is friction-stir welding, which enables gastight, multilayer joints to be welded together without the need for additional welding substances or shielding gases. In contrast to conventional fusion welding processes, the joint is created at a temperature lower than the melting point of the materials, which enables its mechanical and technological properties to meet the highest safety requirements.

“A high level of development and simulation competence is necessary,” concludes Josef Nueschen. “And we can offer that, thanks to our global development network.” EUROGUSS 2020 offers all interested parties an outstanding opportunity to experience Nemak’s competence at close quarters through its battery housing model.